HKNC-450J – 5-Axis CNC Sawjet & Waterjet Machine for Stone Fabrication

Product Overview

The 5 Axis Stone CNC Sawjet HKNC-450J is a groundbreaking dual-function machine integrating a 5-axis CNC saw and a 5-axis CNC waterjet for precision stone processing. Equipped with the advanced Italian ESA CNC control system, it revolutionizes the cutting of granite, marble, quartz, limestone, and advanced ceramic materials. Designed for high-volume production and intricate fabrication, this machine combines efficiency with unmatched versatility, making it ideal for countertops, sinks, inlay patterns, and complex architectural elements.

Key Features & Benefits

1. Dual-Function 5-Axis System

5-Axis CNC Saw :

Fully synchronized 5-axis motion for cutting slabs, profiling edges, engraving, and drilling.

Automatic blade rotation (0°–360°) and tilting (0°–90°) enable seamless angled cuts and curved surface processing.

Ideal for large-scale production with reduced labor costs and material waste.

5-Axis CNC Waterjet :

Precision abrasive cutting head with 360° rotation and 0°–60° tilt for mitered edges and intricate inlay designs.

Capable of cutting ultra-hard materials like porcelain and composite ceramics with micron-level accuracy.

2. Advanced Automation & Control

ESA CNC System : Ensures high-speed, stable operation with user-friendly programming for complex tasks.

Siemens PLC & Motor Integration : Enhances reliability and energy efficiency during prolonged production runs.

3. High-Performance Components

Super-Pressure Pump : Delivers consistent 50,000 PSI cutting force for smooth, burr-free finishes.

Multi-Tool Integration : Combines milling, drilling, saw cutting and waterjet cutting into a single workflow, eliminating the need for secondary machines.

4. Versatile Applications

Saw Module : Perfect for slab cutting, sink fabrication, and edge profiling.

Waterjet Module : Excels in creating delicate mosaic patterns, miters, and 3D shapes for luxury interiors.

Why Choose HKNC-450J?

Cost Efficiency : Dual functionality reduces equipment investment and floor space.

Precision & Speed : 5-axis interpolation ensures rapid, error-free production.

Future-Ready : Supports emerging materials like sintered stone and ultra-compact surfaces.

| Specification |

Value |

Unit |

| Diameter of saw blade |

ø350–ø450 |

mm |

| Dimension of working platform |

4150 x 2250 |

mm |

| X axis stroke |

3500 |

mm |

| Y axis stroke |

2000 |

mm |

| Z axis stroke |

500 |

mm |

| Max. cutting thickness |

100 |

mm |

| Max. lifting stroke |

320 |

mm |

| Power of saw blade motor |

26.4 |

kW |

| Power for abrasive waterjet |

37 |

kW |

| Max. operating water pressure |

450 |

MPa |

| Required pressure of inflow |

0.4 |

MPa |

| Water consumption |

11.4–16.7 |

L/min |

| Gross weight |

10,000 |

kg |

| Dimensions (L x W x H) |

6000 x 3820 x 320 |

mm |

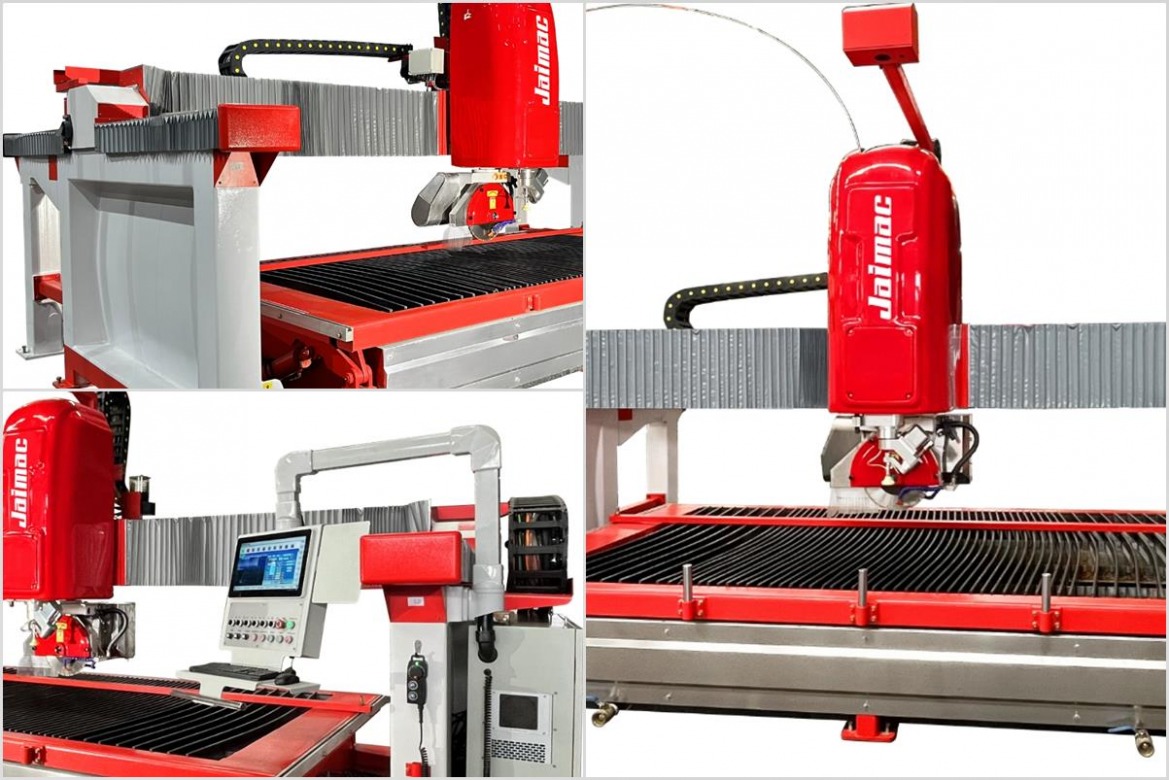

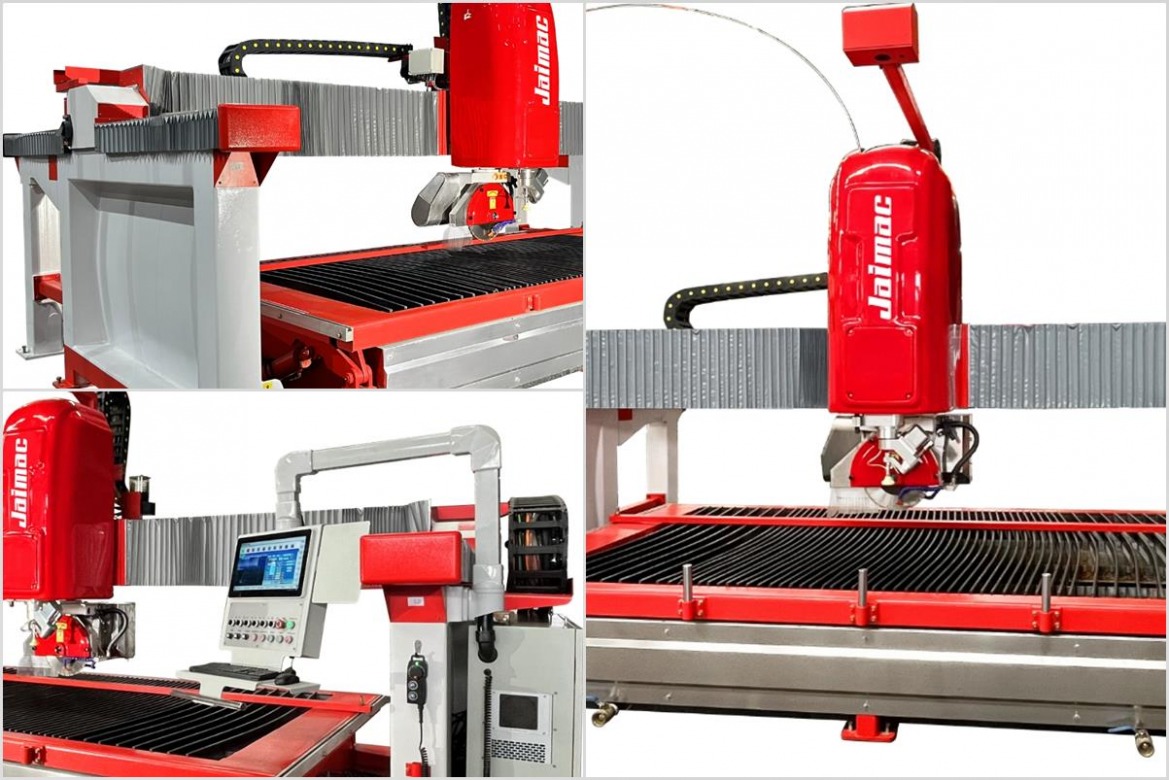

HKNC-500 – 5-Axis CNC Stone Cutting and Shaping Machine for Marble, Granite, Quartz

HKNC-500 with 5 axis interpolation controlled, is a multifunctional CNC stone cutting, shaping and engraving machine built with the needs of workshops in mind, combining simplicity with maximum versatility for a minimum investment budget. It is popularly used for cutting slabs and blocks of both natural and synthetic stone, and ceramic.

Functions:

* make vertical, inclined& horizontal Cut with Disc Blade

* cut curves with Contour Cutting

* machine with the Core Tool such as drill, end mill & excavation wheel

* Incremental routing for sink cutting, profiling & engraving

Match these capabilities with Italian ESA CNC system, digital servo motors and Zues CAD CAM drawing software to make all kind of cuts with ease. HKNC-500 can also been equipped with a vacuum manipulator for the automatic moving of slabs to optimise workpiece usage during the cutting process.

| Specification |

Value |

Unit |

| Diameter of saw blade |

ø400–ø500 |

mm |

| Dimension of working platform |

3300 x 2000 |

mm |

| Max. cutting length |

3300 |

mm |

| Max. cutting thickness |

140 |

mm |

| Max. lifting stroke |

250 |

mm |

| Max. lifting weight by suction cups |

200 |

kg |

| Power of main motor |

11 |

kW |

| Power of cutter frame reciprocating motor |

2 |

kW |

| Power of crossbeam shifting motor |

1.1 |

kW |

| Power of hydraulic station motor |

2.2 |

kW |

| Power of lifting motor |

0.85 |

kW |

| Gross power |

16 |

kW |

| Water consumption |

2 |

m³/h |

| Gross weight |

5400 |

kg |

| Dimensions (L x W x H) |

5700 x 3260 x 2765 |

mm |

Features

-

5-axis interpolation control with Italian CNC Esa system

-

User-friendly interface with 19" color touch screen for easy operation

-

Blade rotation from 0° to 360° and tilt up to 90° for chamfering at any direction or angle

-

Working platform tilts 85° for easy slab loading

-

Manual cutting mode available for simple machining

-

Manual/automatic nesting to optimize slab usage and reduce waste

-

Sole engraving module with electric spindle – excellent for 2D carving

-

Vacuum manipulator – for easy workpiece handling and repositioning

-

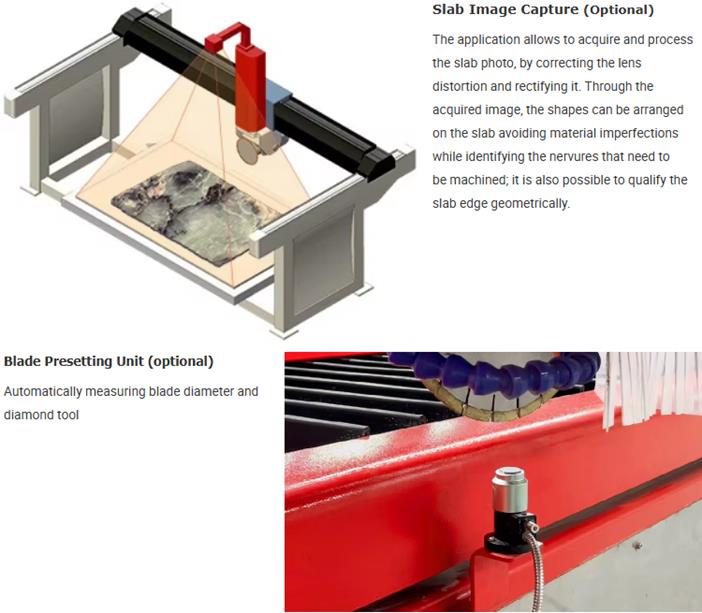

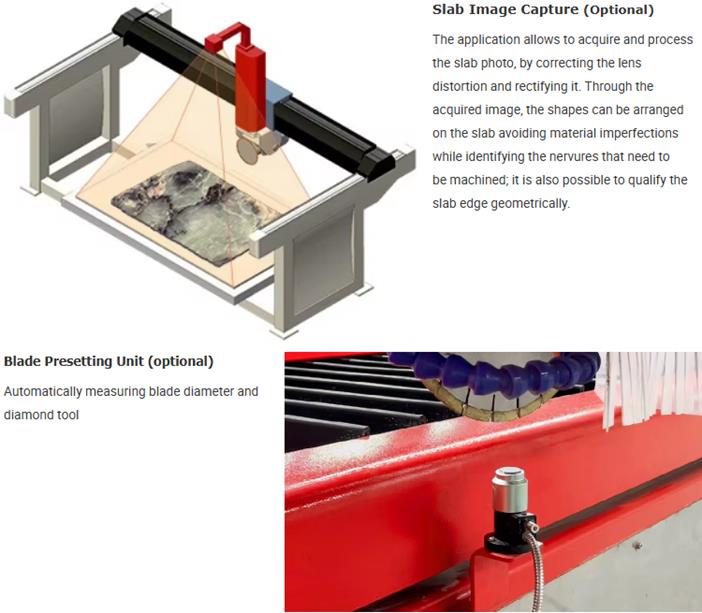

Photo slab – for slab imaging, nesting planning, and defect avoidance

-

Vein match – for seamless vein and color matching across joints

-

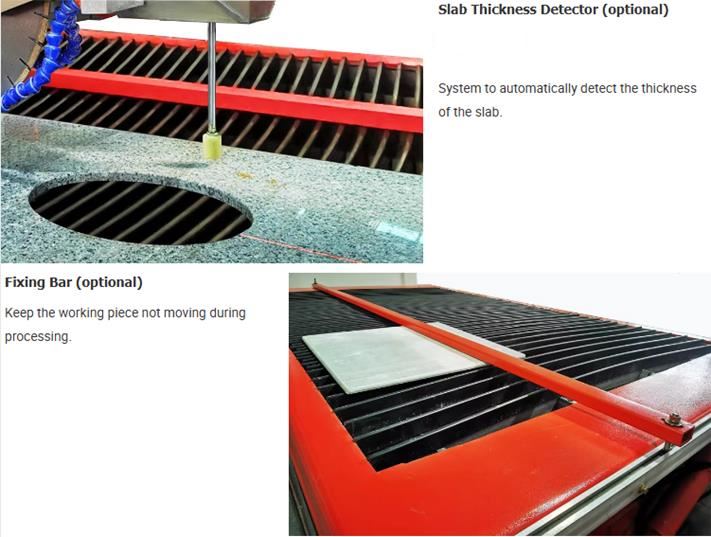

Slab thickness probe – automatically detects slab thickness

-

Tool measuring system – for automatic tool diameter measurement

-

Retractional electric spindle – retractable for efficient tool switching

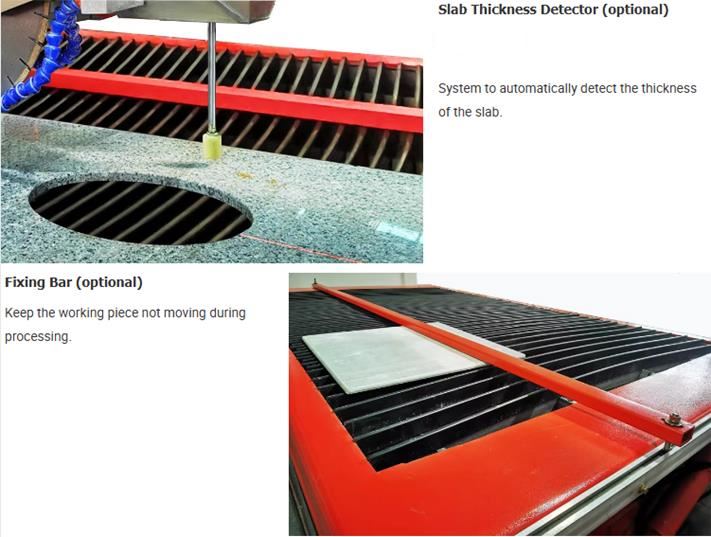

HLSQ-450 – Automatic Bridge Saw for Granite, Marble and Quartz Slab Cutting

The Hualong HLSQ-450 is a monoblock Automatic Bridge Stone Cutting Machine powered by a Siemens PLC control system, designed for high-precision cutting of granite, marble, quartz, and engineered stone slabs. Its advanced 3-axis CNC interpolation, ±270° rotating cutting head, and fully programmable tilting/rotating worktable ensure versatile and efficient material processing.

Key Features

1)Robust Monoblock Design

Easy transportation, installation, and foundation-free setup for rapid deployment.

2)Premium Components

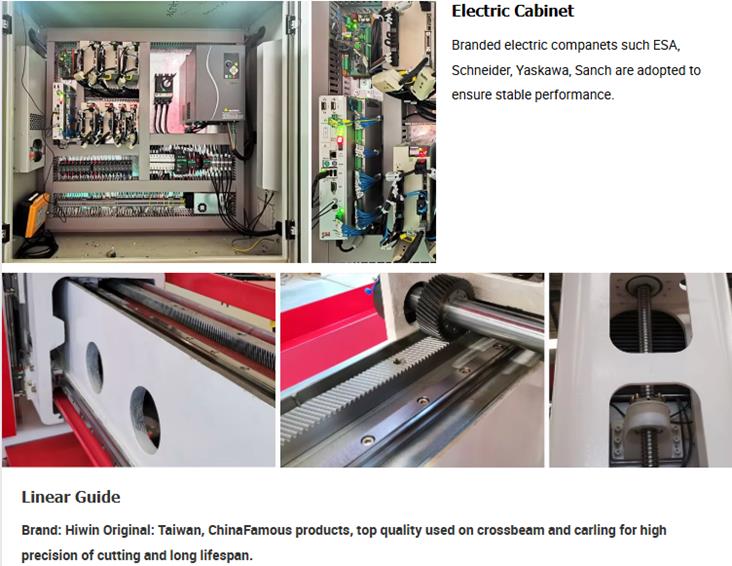

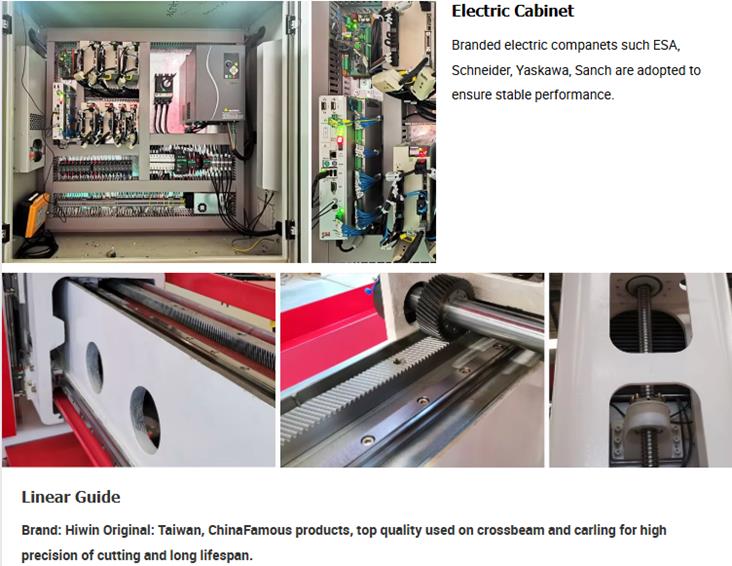

Siemens PLC, Schneider electric systems, and Hiwin linear guides ensure reliability and durability[2][5].

3)Advanced Automation

Automatic blade rotation (0°, 90°, 180°, 270°) and 45° tilting for chamfering cuts.

One-button cross-cutting repetition and remote-controlled worktable rotation (0-360°) and tilting (0-85°) for seamless operation.

4)Flexible Control

Manual mode for simple tasks and programmable CNC functions for complex geometries.

Applications

Ideal for:

Natural & Engineered Stone Fabrication : Precise sizing of slabs, tiles, and countertops.

High-Volume Production : Optimized for repeatable cuts and industrial workflows.

Custom Projects : Versatile tilting/rotating functions for intricate designs.

| Specification |

Value |

Unit |

| Configuration |

| Diameter of saw blade |

Φ400 - Φ450 |

mm |

| Dimension of working platform |

3300 x 2000 |

mm |

| Power of main motor |

15 |

kW |

| Power of tool slide reciprocating motor |

1.1 |

kW |

| Power of crossbeam shifting motor |

1.5 |

kW |

| Power of hydraulic station motor |

2.2 |

kW |

| Power of elevator motor |

1.5 |

kW |

| Gross power |

21.3 |

kW |

| Main Performance Parameters |

| Max. length of horizontal cutting |

3300 |

mm |

| Max. thickness of cutting |

90 |

mm |

| Max. lifting travel of cutter |

300 |

mm |

| Water consumption |

2 |

m³/h |

| Measurement |

| Gross weight |

5400 |

kg |

| Dimensions (L x W x H) |

5700 x 3260 x 2765 |

cm |